Rotary Torque Sensor Non-Contact 50 Nm to 50000 Nm

Rotary torque sensor with two shafts and shaft keys, equipped F/V or F/I signal converter to output standard voltage/current signal.

- Capacitive range 50/500/1000/3000/10000/50000 Nm

- Output signal 10kHz±5kHz, 4-20mA, 0-10V, RS485, etc.

- Accuracy 0.2%F·S or 0.1%F·S for choose

- Acceptable maximum speed 6000rpm

- For either bidirectional or unidirectional measurements

Specification

| SKU | ATO-ZJ-A | |

| Rotary Torque Sensor | Shipping weight | 5~110kg |

| Capacity range | 0-50 Nm ~ 0-50000 Nm | |

| Accuracy | 0.2%F·S, 0.1%F·S | |

| Power supply | ±15V ±5% DC (≥50mA), 24V DC | |

| Output signal | 10kHz±5kHz, 4-20mA, 0-5V, 1-5V, 0-10V (add signal converter), RS485 | |

| Max. speed | 6000rpm | |

| Speed range | 0-1500rpm, 0-3000rpm, 0-4000rpm, maximum speed 6000rpm | |

| Speed signal | 60-2000 pulse/turn | |

| Temperature drift on zero | <0.1%F·S/10℃ | |

| Operating temperature | -20℃~+70℃ | |

| Humidity | ≤90%RH | |

| Insulation resistance | >500MΩ | |

| Stability | 0.3%F·S/year | |

| Safety overload | 150%F·S | |

| Breaking load | 200%F·S | |

| Sensitivity | 1±0.2 mv/V | |

| Power consumption | 4W | |

| Bridge voltage | DC 10V | |

| Material | Alloy steel | |

| Protection class | IP65 | |

| Electrical connection | Circular connector | |

| Wiring | ±15V DC: Red: V+, Blue: V-, Green: Speed output, Yellow: Torque output, Black: GND 24V DC: Red: 24V DC, Blue: Signal-, Green: Speed output, Yellow: Torque output, Black: GND |

|

| Cable length | 2m (Φ5mm), or other customizable lengths | |

| Signal Transmitter |

Power supply | ±15V DC, 24V DC (±0.4V) |

| Power supply dissipation power | Less than 1W | |

| Response time | ≥100mS | |

| Conversion accuracy | ±0.1%F·S | |

| Signal input | Optoelectronic isolation. It is used with rotary torque sensor. | |

| F/V signal output | 0-5V, 0-10V | |

| F/I signal output | 4-20mA | |

| Operating temperature | -20℃~+60℃ | |

| Humidity | 0-90%RH | |

| Wiring | ±15V DC: Red: V+, Blue: V-, Green: Speed output, Yellow: Torque output, Black: GND 24V DC: Red: 24V DC, Blue: Signal-, Green: Speed output, Yellow: Torque output, Black: GND |

|

| Overall dimension (mm) | 158*95*55 (L*W*H) | |

| Istallation dimension (mm) | 143*43, 4-M3 | |

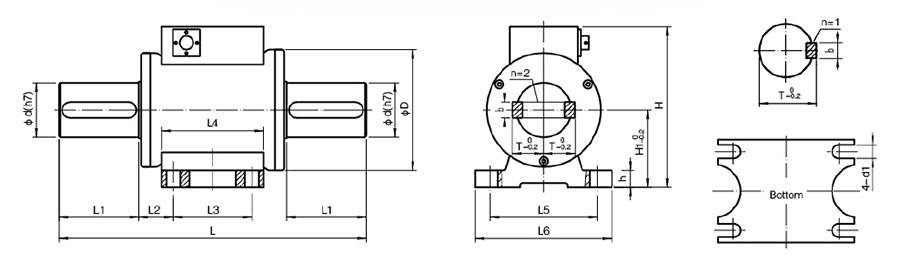

Dimensions

| Capacity Range | Overall Dimension (mm) | Shaft Couping Size (mm) | Base Support Size (mm) | Max. Speed (rpm) | Weight (kg) | ||||||||||||

| H | L | D | d | b(h7)*n | T | L1 | L2 | L3 | L4 | L5 | L6 | H1 | d1 | h | |||

| 50 Nm | 114 | 188 | 78 | 18 | 6*1 | 20.5 | 31 | 31 | 72 | 90 | 75 | 100 | 55 | 8 | 12 | 6000 | 5 |

| 100 Nm | 114 | 188 | 78 | 18 | 6*1 | 20.5 | 31 | 31 | 72 | 90 | 75 | 100 | 55 | 8 | 12 | 6000 | 5 |

| 500 Nm | 135 | 238 | 96 | 38 | 10*2 | 22 | 55 | 55 | 72 | 90 | 75 | 100 | 65 | 8 | 12 | 4000 | 8 |

| 1000 Nm | 143 | 270 | 106 | 48 | 14*2 | 27.5 | 70 | 70 | 69 | 90 | 78 | 120 | 68 | 12 | 15 | 3000 | 10 |

| 3000 Nm | 143 | 270 | 106 | 48 | 14*2 | 27.5 | 70 | 70 | 69 | 90 | 78 | 120 | 68 | 12 | 15 | 3000 | 25 |

| 5000 Nm | 187 | 347 | 144 | 75 | 20*2 | 42 | 105 | 105 | 69 | 100 | 156 | 180 | 90 | 12 | 15 | 2000 | 25 |

| 10000 Nm | 214 | 389 | 158 | 98 | 28*2 | 55 | 118 | 118 | 80 | 110 | 170 | 200 | 110 | 14 | 15 | 2000 | 40 |

| 20000 Nm | 225 | 420 | 168 | 105 | 28*2 | 28.5 | 125 | 125 | 88 | 125 | 180 | 205 | 115 | 14 | 15 | 1800 | 60 |

| 50000 Nm | 301 | 480 | 240 | 150 | 40*2 | 84 | 150 | 150 | 90 | 125 | 190 | 350 | 153 | 18 | 20 | 1500 | 110 |

All torque sensors and repair services provided by ATO Torque Sensor are covered by a limited warranty against defective material and workmanship for a period of one year from date of original purchase. Contact ATO for a complete statement of our warranty. Mechanical damage to equipment due to improper use is not covered by warranty. Electronic circuitry failure caused by the introduction of unregulated or improper excitation power or electrostatic discharge is not covered by warranty.

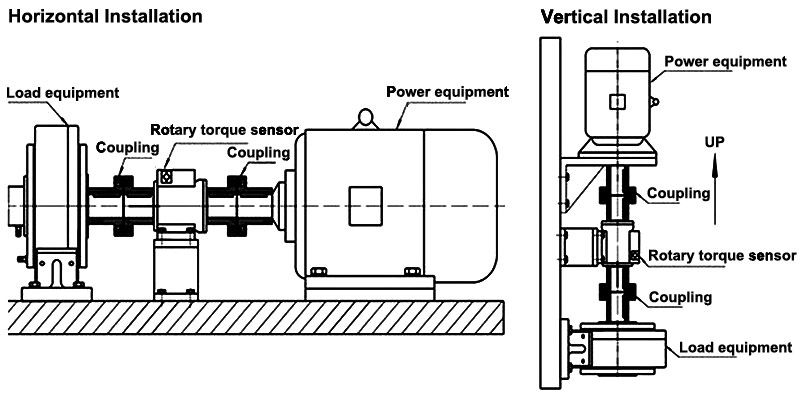

For proper electrical connections, refer to the installation drawing for the torque sensor, and the wiring drawing for the digital torque meter used. Construct the interconnect cable from high-quality shielded instrumentation cable. Various cable assemblies are available through ATO Torque Sensor. Connect one end of the cable to the sensor connector and the other end to the digital torque meter. Make sure to tighten the cable connector to the sensor. For installation in dirty, humid, or rugged environments, it is suggested that the connection be shielded against dust or moisture with shrink tubing or other protective material. Strain relieving the cable/sensor connection can also prolong cable life. Mounting cables to a test structure with tape, clamps, or adhesives minimizes cable whip.

Refer to the dimension drawing supplied for specific outline dimensions and installation details.

The calibration steps are as follows:

- Apply the rated value of torque to the torque sensor and then remove it again.

- Adjust the zero reading accurately.

- Apply a known value of torque to the torque sensor.

- Adjust the displayed reading to the corresponding value.

Plotting a calibration curve:

- Calibrate the torque sensor as described above.

- Apply torque in 1/10 steps up to the full rated value and then remove it again in the same way.

- A delay of at least 30 seconds must be allowed between the individual 1/10 steps so that each reading can stabilize before it is recorded.

Failure of the sensor structure or fasteners used in its installation may cause personal injury and equipment damage. To prevent structure failure, review the extraneous load limits listed on the specification. Extraneous load limits are extraneous side force, thrust and bending moment that may be applied without electrical or mechanical damage to the torque sensor. Do not exceed moment or shear whichever attained first. Measurement inaccuracy and structure damage may result. Install the sensor in a manner that minimizes these loads. In addition, review data from manufacturers of fixtures and fasteners used in the sensors installation to determine if failure might occur due to these loads.